When snow is unavailable, skiers will glide on anything: grass, pine needles, sawdust, sand dunes, volcanic ash, carpet, plastic mat, soap flakes, powdered mica and soda crystals.

In 1958, German industrialist Dr Rudolf Alberti (1907-1974) patented the concept of skiing on gravel. Alberti owned a mine in the Harz Mountains (still going today) that produced barium sulphate – a bright white dye -- and calcium fluoride. The ore contained barite, or heavy spar, a very dense mineral used today in x-ray shielding, rubber mudflaps and oil-drilling mud. American industry alone uses about 3.3 million tons of the stuff annually.

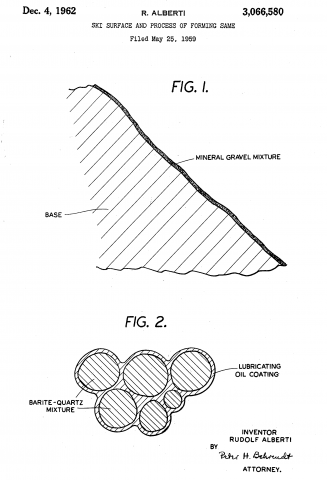

Alberti noticed that barite nodules have a very low friction co-efficient and is dust free. He built a 1,300 feet (400 metre) long ski run and covered it with a mix of river gravel and barite, about six inches (15cm) deep.

Contemporary reports record the surface proved pretty good for skiing, but that skis disintegrated due to the heat generated. Alberti ordered up a stock of skis with steel bases, and with a concrete mixer coated the gravel with used engine oil. This reportedly “dramatically increased ski speed but producing some hair-raising results and near disastrous falls.” Alberti received patents in Germany and the United States.

The slope does not appear ever to have operated as a commercial venture. But to this day Altberti’s home town St. Andreasberg has a small ski area operated by Alberti-Lifts. –Patrick Thorne