Rossignol, the oldest surviving brand name in skiing, can also claim to be the oldest surviving factory in skiing—for now. Ski production began in Voiron in 1907, and lasted 100 years. The company—then owned by the troubled Quiksilver beachwear marketer—closed that facility in December, 2007. In 2014, some production returned to France -- specifically to Sallanches near Chamonix.

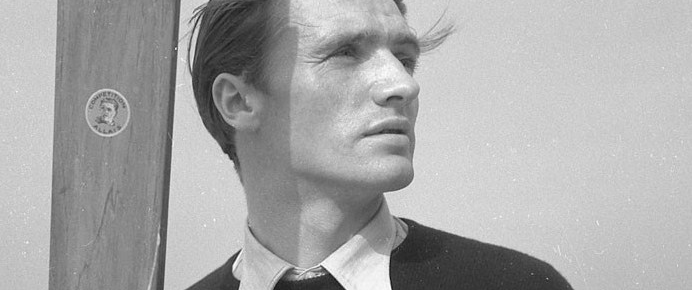

Abel Rossignol

Abel Rossignol was born November 19, 1882. A skilled woodworker, in 1903 he installed, at the foot of the Chartreuse massif near Grenoble, a workshop to make shuttles and bobbins for weaving machinery, needed by the flourishing local textile industry.

Before that time, only a few small French workshops had made skis patterned after the Norwegian Telemark model. In 1903, according to historian John Allen, the French Army established its first ski school, at Briançon, under Capitaine Clerc, with three Norwegian instructors, using a stock of Norwegian skis. The following year, recruiting for the chasseurs alpins was stepped up, and in 1906, Clerc opened a workshop where his troopers built their own skis—about 340 pairs over a period of two years.

In 1906, too, the Club Alpin de France assumed responsibility for developing the sport of skiing. Its first meet was scheduled for Montgenèvre in February 1907. The event was well attended by an international field of civilian skiers from France, Italy, Austria, Switzerland and Norway – and, thanks to heavy support by the French Army, by alpine troops from France, Italy and Switzerland. The meet drew plenty of attention from the press, and nearly 3,000 spectators showed up. Among them was Abel Rossignol, who immediately conceived a passion for the sport and decided to make his own gear, for sale. Lieutenant R. Gelinet, in command of a nearby army post, bought one of Rossignol’s first production lots for his men.

Rossignol’s skis were carved, like most top-quality skis of the era, of solid American hickory or native European ash. They sold well, and he won first prize at a manufacturing trade show in Chamonix in 1909. Then, in 1911, in order to study the sport and trade, he traveled to Scandinavia, visiting all the principal factories. The same year he began participating in the annual meeting of the Touring Club of France. During World War I, Rossignol’s factory made more skis for the French Army.

After the war, the company pursued its twin businesses—weaving-machinery parts and skis—and furnished skis for some of the athletes in the first winter Olympic Games at Chamonix in 1924. It was the start of a long involvement with world-class competition.

Abel Rossignol, Jr. grew up with the sport, and was a good ski racer. One of his racing friends was Emile Allais of Megève, who reached the podium at the Murren World Championships in 1935 (second in downhill and alpine combined), medaled at the Garmisch-Partenkirchen games in 1936 (third in slalom and alpine combined) and was World Champion in 1937. In 1936, Allais began working with Rossignol, especially on new skis for racers.

These were critical years in the evolution of ski racing. For one thing, between 1932 and 1936 alpine racers began clamping their heels down with the new Kandahar bindings; this permitted the Austrian Toni Seelos and Allais to innovate a precise and powerful new parallel race turn.

These were also the years in which manufacturers around the world were able to license and use the Splitkein and A&T patents on laminated skis. With Allais, Abel Jr. designed a laminated ash slalom ski, built in multiple layers. They called it the Olympique, and patented the structure in 1941—hence the Olympique 41, Rossi’s standard wooden race ski through the post-World War II years. A heavier version for downhill and GS was laminated of hickory. Among the stars using Rossignol Olympique skis was Henri Oreiller (1925-1962), the first World and Olympic Champion in downhill in 1948—it was the first year the downhill and slalom medals were separated from the combined medal.

The postwar years comprised another era of technical ferment. In 1947, Dynamic’s Paul Michal had introduced the first celluloid plastic base. By 1949 Michal and an aircraft engineer in the U.S. named Howard Head were building skis with hidden one-piece steel edges, and by 1954 polyethylene was becoming widely available for use as a ski base material.

Emile Allais left for America in 1946 to help build lifts and trails in Quebec and, the following summer, at Portillo, Chile. Then he coached racers in Canada and at Sun Valley, landing at Squaw Valley in 1948 as ski school director. He coached the U.S. Ski Team at Oslo in 1952. Then he returned to France in 1954 to help develop the new ski resort at Courchevel. He brought along several pairs of the new-fangled Head metal skis, dropping at least one pair off with Abel, Jr. in Voiron.

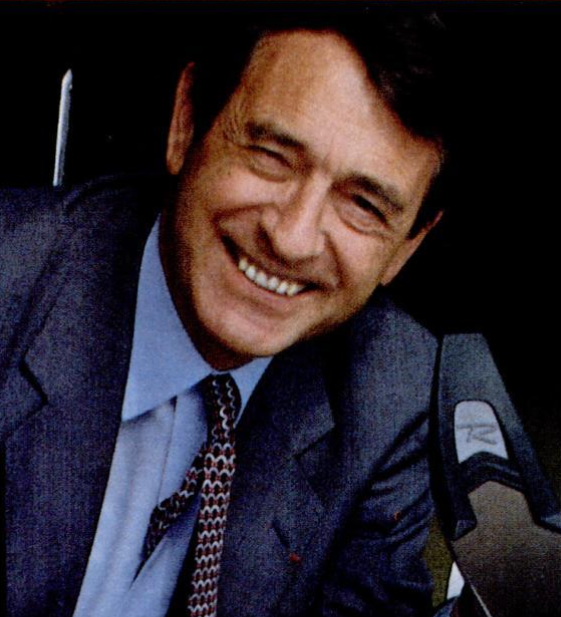

Abel Rossignol died in 1954 at age 72, and Abel, Jr. took over. That year the company made nearly 8,000 pairs of laminated wooden skis, and about 500 pairs of experimental metal skis, riveted together because they couldn’t figure out how to glue them the way Head did. However, in 1955, the textile manufacturing business collapsed and the Rossignol factory ran into serious financial trouble. Ski production couldn’t compensate for the loss of the shuttle-and-bobbin business. At this point Allais contacted Laurent Boix-Vives, a young Savoyard entrepreneur whom he had met at Courchevel in the course of building ski lifts and trails.

Boix-Vives, son of a local grocer in Brides-les-Bains, was born in 1926, and at age 10 had watched Allais win local races. At 18, near the end of the war, his father took him out of school to work in the grocery business, setting up new shops in the tiny mountain towns. Knowing the mountains well, Boix-Vives explored sites suitable for ski trails, focusing on the village of Moriond, which soon became Courchevel 1650. In 1953, the state government began offering contracts to develop lifts there; Boix-Vives jumped on the opportunity and got permission to build six lifts at Bozel, serving about 2,000 vertical feet of terrain, most of it tree skiing down to the valley towns below Courchevel. Eventually he built 21 lifts between Courchevel and La Plagne, and two at la Tania. He told his father the lifts would mean more grocery business. And he was right.

When Allais put him together with Rossignol, Boix-Vives was enthusiastic. At the close of 1955, at age 29, Boix-Vives put up $50,000 and, with an additional investment from Philippe Cognacq and Courmouls Houles, two of his ski-lift partners, assumed control of Rossignol. “We also promised to pay off the factory’s debts within three years,” says Boix-Vives. “It amounted to another $100,000.”

His first move was to focus all activities on skiing. He dropped the weaving business, and reorganized product development under the technical supervision of Emile Allais and Abel Jr.

With Boix-Vives’ funding, Allais and Abel, Jr. jumped straight into development of their own laminated aluminum skis. Adrien Duvillard, one of the top French racers of the era, did some of their on-snow testing. In 1959 Duvillard used the black-topped Allais 60 ski to win the French downhill championship, and the following winter he won every downhill of the season—except the 1960 Olympic downhill, in which teammate Jean Vuarnet won the gold medal at Squaw Valley on the Allais 60. The red-topped commercial version was branded the Allais Major, and it proved to be a great GS ski. “It was clearly faster than hickory skis, because the aluminum vibrated to break up surface tension under the base,” Duvillard says. “By the Chamonix World Championships in 1962, all the French racers were on the Allais, including Guy Perillat and Charles Bozon, who both used the very light Dynamic Leger for slalom but the Allais for GS and downhill.”

Boix-Vives acquired what one of his employees, Jean-Francois Lanvers, later called “blind faith in racing as a promotional vehicle.” He sold his share in the Courchevel lifts and focused on business in Voiron. Boix-Vives concentrated on developing racers, and helped to organize the French factory pool in support of the team.

In the early years of the 1960s, the company’s goal was to strengthen its position on the international scene, since the French market represented only 7 or 8 percent of world ski consumption and was largely supplied by imports. A project was launched to develop sales in Europe (Italy, Switzerland, Germany) first, and then in the U.S. and Japan. Boix, accompanied by Duvillard and Allais, made an initial trip abroad in 1962, and he hired Lee Russel—father of the

future racing star Patrick Russel—as international marketing director. Russell struck a deal with Duvillard to race in North America and Japan on Rossignol skis, and Duvillard folded these trips into the product-testing cycle.

Rossignol’s distributor in the U.S. to that point had been the Connecticut retailer Gus Sunne. In 1962, Roby Albouy opened a Rossignol USA headquarters in Aspen, with Hans Hagemeister and Wolfgang Lert as Western sales reps and Erich Boeckler handling sales in the East; Raymond Lanctot headed up sales in Canada. Later, the brand would be handled by national sporting goods wholesalers: first, Garcia (which sold Fischer, Marker, and Humanic as well), and later by Wolverine World Wide, the Michigan-based boot company that was already importing Le Trappeur products. At this point, Rossignol began sending French ski coaches over to manage its North American sales. The cast would eventually include Henri Patty and Gerard Rubaud.

By 1960, too, fiberglass was becoming available in commercial quantities. In North America, Plymold and Toni Sailer skis had already reached the market. European and Japanese factories resorted to slathering wood skis with resinous polyester or epoxy preparations, just so they could claim to have a “plastic” ski. Rossignol’s version was called the Epoxum. Wooden skis were still best for slalom (the three medalists in the 1964 Olympic slalom all used the ash Kastle Slalom, and Guy Perillat set the fastest first-run time on the Dynamic Leger before straddling a gate in the final. Rossignol produced a light wooden slalom ski called the Plume (feather)—too light, Duvillard remembers, because it often broke. It was time to get serious and turn glass-reinforced epoxy materials into a truly engineered competition ski. Rossignol entered a technology race with Dynamic and Kneissl to figure out how best to use fiberglass in racing skis.

In 1961, the engineer Gaston Haldemann had begun working on a hollow-core slalom ski he called simply the Rossignol Fiberglass, and in 1963 Duvillard took that ski to America where he raced on it successfully on the early pro circuit. Even at this late date, the company had no special race department. Instead, Allais and Abel, Jr. went through the annual production of Olympique model skis and hand-picked the best pairs to give to racers. In 1964, Allais set up a special atelier, under an expert Italian woodworker named Angel Nocente, just to make skis for racers. He also hired a young racing coach named Gerard Rubaud, the son of one of his friends, and they set out to match ski flex and performance to what individual racers needed. Duvillard took charge of the on-snow testing program and Roger Abondance managed relations with active racers and teams.

The race shop team began its fiberglass work in 1964 with a glass-clad ski built up on the ash core of the Olympique. The engineers Maurice Woehrle and Maurice Legrand determined that they needed a thinner, lighter, softer-flexing structure for the glass ski, and the result was the Strato, introduced for the 1965 season, retaining the Olympique sidecut dimensions. It was a spectacular success, and export sales took off. The name referenced the multiple layers of wood in the ski: three layers of laminated ash or hickory, lightened with strips of low-density tropical woods, with additional layers of epoxy-reinforced fiberglass above and below.

Abel, Jr. retired that year, as his creation, the Olympique, went out of production.

The World Championships in 1966 would prove a watershed in promoting the Strato. Boix-Vives determined that, to promote export sales, he needed to focus world attention on the Rossignol brand. He sent Rubaud to Portillo with plain burgundy-top skis. Four French skiers (Jean-Claude Killy, Guy Perillat, Marielle Goitschel, and Annie Famose) won six gold medals, and Rubaud put Rossignol stickers on the skis. Rossignol’s metal downhill skis got the brown topskin, too, meaning that the name Allais disappeared.

“Emile never again visited the factory,” Rubaud recalls. After a falling out with Boix-Vives, at the close of the 1966 season, Allais ended his 30-year relationship with Rossignol.

These were growth years in skiing, but making skis was a highly competitive, capital-intensive business, and not every factory prospered. While the French ski team forged ahead, on French skis, to become the dominant power in racing, the new Dynastar factory in Sallanches, near Chamonix, was barely paying its bills. In 1967 the plant grossed 16 million francs—about $3.2 million at then-current rates—and lost 16 million francs. Boix-Vives bought the company for a single franc, thus acquiring a second production facility.

In some ways, the era from 1968 to 1972 was the top of the arc. Canada’s Nancy Greene established a solid Rossignol brand franchise by winning everything in sight on Stratos, and America’s Barbara Ann Cochran won her gold medal on Rossignols at Sapporo. Meanwhile, most of the top French and American men diluted their brand value by bouncing around among Rossignol, Dynamic, and Head. Jean-Claude Killy, for instance, usually skied GS on Rossignol Stratos, slalom on Dynamic VR17s, and downhill on whatever was fastest. The exceptions were the Grenoble Olympics, when he skied all three events on Dynamic skis. Then, to even things up with Rubaud and his friends at Rossignol, he skied Rossignol for the rest of the World Cup season. Leo Lacroix skied Stratos for GS, but after the 1966 World Championships at Portillo, where he won silver in the downhill and alpine combined, he began building his own skis, and won with them. From 1968 onward, Rossignol athletes never failed to win at least seven medals in any Olympiad.

In 1970, Rossignol built a new, fully modern plant near Barcelona. In these pre-Euopean Union days, Spain was a cheap-labor country, and the new factory would become, over the next 30 years, Rossignol’s biggest, most efficient facility. Another acquisition that year was the Authier factory in Stans, Switzerland, which had been operated by Olin for a few years when the American company was still building its Connecticut ski plant. Gaston Haldemann took over the Stans plant to build his hollow-core, all-fiberglass skis. The race version was rebranded as the Rossignol Equipe Suisse, and proved a huge success in downhill—especially at the Sapporo Olympics, where Switzerland’s Bernhard Russi and Roland Colombin took gold and silver, while Switzerland’s Marie-Therese Nadig won the women’s race.

Haldemann’s hollow skis notwithstanding, all of Rossignol’s race skis to this point had wooden cores. These could be inconsistent in flex and camber, Duvillard now says. That wasn’t a big issue for hand-picked, hand-matched race skis, but it wasn’t a good quality in a mass-production ski. To improve the consistency of the production skis, the engineers began using foam cores, which could be counted on to be identical pair after pair for runs of thousands of pairs. After 1970, the race department began using foam cores for some of the slalom and GS skis – and planning to turn some of these foam-core race skis into mass-produced products.

The first generation of production foam race skis—the metal Roc 550 for GS and the ST-650 for slalom—reached the market in 1972. At this point, Rossignol was the number one brand in the world. Boix-Vives was honored in 1976 by Prime Minister Raymond Barre with the title Manager of the Year. New factories went up in Vermont and Quebec, and Rossignol bought tennis racquet factories in Maine and Massachusetts. The tennis venture proved disastrously mistimed, as Rossignol ran straight into Howard Head’s new oversized Prince racquet.

Boix-Vives set up wholly owned distribution companies in North America for Rossignol and Dynastar, headquartered in Williston and Colchester, Vermont. Rossignol took over its own distribution in all major markets. North America soon provided 40 percent of Rossignol’s annual volume.

In 1973, the U.S. economy was hit with a double-whammy: National debt had soared to pay for the Vietnam war, which led to higher interest rates, and the first OPEC oil embargo sent gas prices zooming—and to weekend gas rationing, just when customers wanted to go skiing. Moreover, with the rise of freestyle and mogul skiing, racing was no longer perceived as the premium venue for marketing skis—and that hurt Rossignol in particular.

Rossignol’s engineers tackled the design of freestyle skis with great success. “We won the PFA (Professional Freestyle Associates) Manufacturer’s Trophy in the second year of our involvement,” recalls Hugh Harley, who managed the freestyle program. But the marketing impact was diluted, as Rossi had to compete for attention with a number of upstart brands – Hart, Olin, The Ski – with no presence in racing at all. For a couple of years in the mid-70s, the best-selling ski in the world was not the Strato – but the bright orange Olin Mark IV.

Ski sales flattened. Boix-Vives reacted by diversifying into new product lines: Rossignol launched a fabulously successful joint venture with Nordica to distribute the boots in North America, then introduced cross-country skis in 1976, bought the Lange boot factory in 1978, and built a ski pole factory in 1980. Lange was a personal investment: Boix-Vives bought it through his own holding company, Ski Expansion, which owned 38 percent of Rossignol S.A. Only 49 percent of Rossignol stock was publicly traded, so Boix-Vives was assured of control. For some years, Lange distributed its own brand of skis made in the Authier factory.

The rising U.S. dollar and sky-high American interest rates made it more and more expensive to operate the American ski and tennis factories. The era was hard on all North American ski enterprises: within a two-year period, companies like A&T, Hanson, and Hexcel closed their doors. In 1981, the book value of Rossignol stock on the Paris exchange sank below $25 million. In 1982, Boix-Vives ordered the U.S. factories shut down, laying off hundreds and firing senior managers.

The year 1982, happily, was the launch season for a new revelation in ski technology—the “vibration absorbing system” designed by engineer Yves Piegay. Ski companies had been selling “damping” for years, building thick layers of rubber or “constrained viscoelastic layers” into high-speed skis in an attempt to deaden vibration. The result, more often than not, was a dead-feeling ski. Piegay figured out that short, inconspicuous lengths of what amounted to tire cord— steel wires embedded in thin strips of rubber—placed at just the right “nodes,” could control a ski’s vibration without affecting lively feel. Duvillard recalls the testing program that led to the VAS models was the most fun he ever had at Rossignol. “We kept moving the little dampers around, two centimeters at a time, and kept the ones that worked. We had some really good skis to begin with, the SM and FP race skis, so nothing very scary ever happened. But the skis got better and better as we zeroed in the final designs.”

The SM VAS, in particular, was a fabulous high-speed recreational ski, unusually supple for a GS ski but perfectly stable. A good skier could use it on the race course, then dive into the back bowls without missing a turn. It was wildly popular at the top end of the line—the most profitable segment. Rossignol profits rebounded. By 1984, market capitalization had more than doubled to $52 million.

Boix-Vives resumed a program of sports acquisitions. He bought Jean-Claude Killy’s Veleda clothing factory in 1984, and Cleveland Golf in 1990. In 1994 Rossignol acquired the Look and Geze binding factory in Nevers, and the Caber factory in Montebelluna, rebranding these products with the Rossignol logo. Ownership of Lange was folded into the Caber operation, and the two factories shared their race boot technology. The empire sold off the Authier plant to a group of local Swiss investors and placed distribution of Lange boots and Look bindings with the Dynastar organizations worldwide.

The consolidation came just in time. In 1989 Rossignol acquired a powerful new competitor in the ski market—Salomon. Over the next five years Rossignol would scramble to match Salomon’s sleek and well-marketed cap ski technology, and then, after 1993, play catch-up to Elan, K2, and the Austrians in the new shaped-ski revolution.

During the 1990s, companies that moved more quickly into new ski technology gained market share, largely at the expense of Groupe Rossignol ski brands. Success in the boot and binding markets kept the company profitable. According to Hugh Harley, president of Rossignol’s U.S. operation at the time, the highly automated efficiency of the Spanish factory, which retooled quickly to build less-expensive shaped skis, enabled the ski division to squeak through and regain prominence in the low price points.

Boix-Vives wasn’t an equipment or machinery designer like his rivals Paul Michal, Alois Rohrmoser, or even a product fanatic like Josef Fischer or Georges Salomon. He was a bona fide ski racing nut, putting nearly 3.5 percent of gross sales straight into Roger Abondance’s powerful racing operation. But first and foremost, Boix-Vives was a financial wizard. “Time and again he was able to turn around companies in trouble,” said Lanvers. “Part of it is that he set up a clever organization to sell currency futures and make currency fluctuations work for him. But the most important thing is that he had the ability to divorce himself from the nuts and bolts, step back, and see the big picture.”

Boix-Vives himself made the same point a bit differently. “Having a strong dollar is like a new Marshall Plan,” he said. “There are millions of workers around the world producing for America.” In fact, Rossignol’s fortunes rose and fell on the strength of the dollar. When the dollar was strong, Rossignol’s profits soared and the company was able to spend a great deal of money on product development—which in Boix’s mind usually meant new designs for race skis, boots, and bindings. Throughout, product development progress was marked by thousands of World Cup victories and hundreds of Olympic and World Championship medals. The 50-millionth Rossignol ski was built in 2004.

Duvillard and Abondance retired during the 1996-97 season. “Roger’s departure left a big hole in the racing organization,” Duvillard now says. The results showed up on the podium: while Nordic athletes continued to deliver dozens of victories on Rossignol gear, the medal count on the alpine side dropped sharply after 1997, as Rossignol lost—and was unable to replace—hot properties like Picabo Street and Bode Miller.

During the new millennium, the dollar dropped to historic lows relative to the Euro—hitting EUR .76 in 2005. Rossignol’s profitability plummeted. Part of the problem was that Rossignol was still making skis and boots in Western Europe, while most of the competition— including the large Austrian companies—had reacted to the sinking dollar by moving much of their factory capacity to China, the Ukraine, Romania, Bulgaria and other cheap-labor nations. To keep prices competitive, Rossignol had to slash its wholesale margins. The 2003-2004 and 2004-2005 winters saw late snow in key markets, and sales stalled. Rossignol posted a solid loss.

In March 2005, at age 78, Boix-Vives faced retirement. He sold his controlling interest in Rossignol to the Australian/American sporting goods company Quiksilver, then run by his friend Bernard Mariette. SEC filings show that the terms of the sale valued Rossignol at approximately $312 million, with debt about $158 million and revenue of $630 million. The deal included a $55 million cash payout to Boix, but apparently treated his original partners, Philippe Cognacq and Courmouls Houles, as common stockholders.

Boix-Vives stayed on as president of Rossignol’s golf division. Quiksilver consolidated all North American snowsports operations—Rossignol, Dynastar, Lange, Look, and their related snowboard divisions—in Park City, Utah, and sold the Voiron factory grounds to a real estate developer.

In theory, it makes sense for a “summer” sporting goods company like Quiksilver to acquire a wintersports brand, to even out cash flow through the year. In practice, as Spalding found after buying Persenico and Caber, and as Adidas found after buying Salomon, it doesn’t quite work that way. Ski companies have only a single product turn each year, compared to four or six or eight product turns for an athletic clothing or shoe company; margins are lower, debt levels higher, and a warm winter can stop sales cold. Sure enough, the Rossignol purchase was followed by a couple of scratchy winters, and the Rossignol division dragged Quiksilver’s annualized profit from 90 cents per share in 2005 to 75 cents in 2006 and a 2 cent per-share loss in the first half of 2007—its first loss since 1992. Several board members—including Boix-Vives—resigned in the spring of 2007. And then, on July 2, The Wall Street Journal reported that Quiksilver—having lost $50 million in wintersports—wanted to sell the Rossignol division. In 2008, the company was acquired by the Australian bank Macquarie. In July 2013, Macquairie sold the Rossignol Group, along with its subsidiaries Lange and Dynastar, to a partnership of Altor Equity Partners (a Swedish investment group) and the Boix-Vives family.

To celebrate its 100th Anniversary, Rossignol built a limited number of skis using Olympique 41 and Strato topskins on modern non-racing B2 and B3 structures—they are shaped, aluminum- reinforced, foam-core, cap-top high performance recreational skis, mid-fat and fat skis respectively. These are skis for today, with tops from the past—symbolic, perhaps, of the brand’s uncertain future.

This article is based on the author’s 1986 interview with Laurent Boix-Vives, along with recent material from a variety of French sources, including a recent book by Jean-Jacques Bompard, a retired director of Rossignol, and interviews with Adrien Duvillard, Gerard Rubaud, Jean-Pierre Rosso and Jacques Rodet. Thanks to E. John B. Allen for information from his new book The Culture and Sport of Skiing: From Antiquity to World War II.

Also see Maurice Woehrle’s technical history of Rossignol ski production, in French.